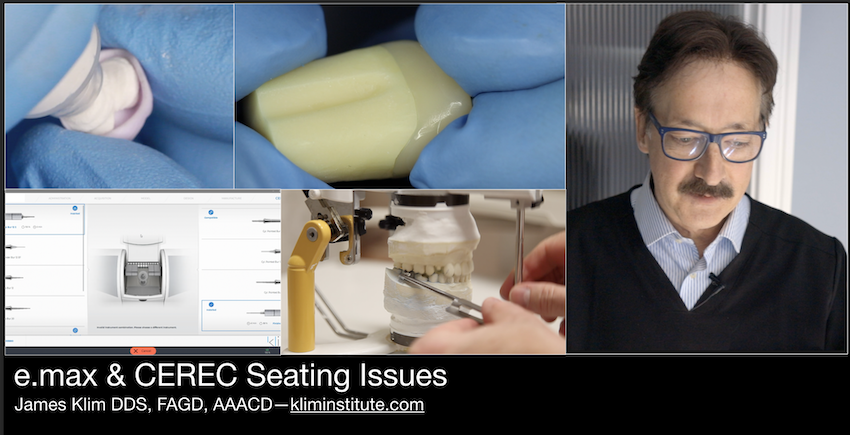

Here is a question I often hear, "how do I deal with e.max binding after crystallization"? I have seen this issue discussed in several FaceBook group threads. This video will share my take on this issue and provide a few pointers on how to deal with the e.max binding issue if that is happening in your clinical theater.

e.max will shrink when crystalizing. The following are solution pointers to avoid the post e.max binding issue.

- Calibrate camera

- Calibrate milling unit

- Spacer 120

- Use the left 12 bur rather than the 12S bur

- Fine mill rather than the fast mill.

- Preparation 6-9 degrees tapper with rounded axial to occlusal angles.

- Calibrate the firing furnace.

- Fill e.max restoration with object fix, make sure full internal and margin support, and place in the center of the furnace for firing.

- Work out the fit on a model where the die can be removed and margins observed. I calibrate on models all the time on new software and hardware releases. Not all CEREC systems are the same parameter metrics. If you see binding at 120 microns, then keep raising the parameter until the fit drops in!